Home >

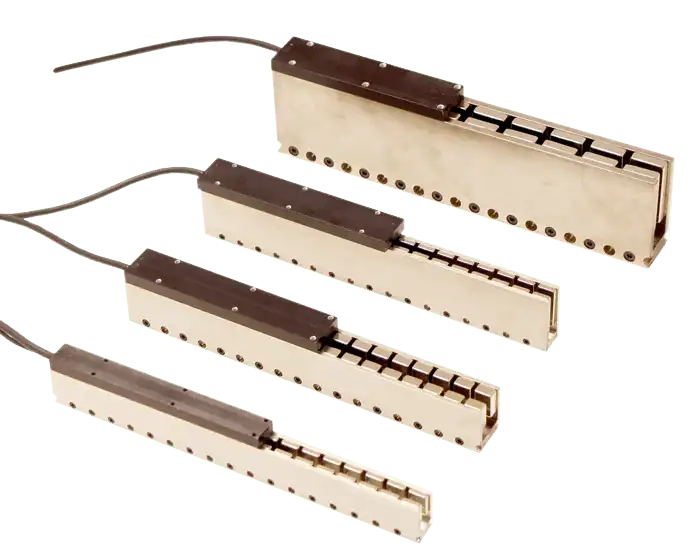

Airex™ Ironless Linear Motors

Airex's ironless linear motors utilize powerful permanent magnets and lack iron in their coils, reducing inductance and improving response times. They excel in precision applications, offering low heat rise and high bandwidth. The P-Series and C-Series motors feature high force density, compact designs, and superior performance. Airex motors are customizable, with options for mounting, cables, thermal sensors, and vacuum compatibility. These motors provide unmatched performance in direct drive systems, eliminating issues like backlash and wear.

Specifications Overview

P-Series

The P-Series is our workhorse, sporting our highest force density, superb electrical phase balance, flexible in-field electrical connection choices and the largest number of configurable options, resulting in motor implementations with the highest-degree of veracity.

| units | P12 | P15 | P16 | P20 | |

|---|---|---|---|---|---|

| Coil and Magnet Track Assembly Width | mm | 19.05 | 28.58 | 19.05 | 35.00 |

| Coil and Magnet Track Assembly Height | mm | 38.35 | 45.21 | 54.14 | 86.86 |

| Coil Lengths (Inside Magnet Track) | mm | 30.7 - 244.1 | 30.7 - 305.1 | 30.7 - 244.1 | 61.2 - 366.0 |

| Magnet Track Length | Configurable in 30.5 mm increments | Configurable in 61.0 mm increments | |||

| Continuous Force | N | 11.9 - 95.3 | 17.3 - 173 | 17.8 - 176 | 70.6 - 424 |

| Peak Force | N | 38.0 - 301 | 55.0 - 547 | 70.0 - 557 | 223 - 1340 |

| Connection Options | Delta or Wye; Series or Parallel | ||||

| Sensor Options | Hall Effect Sensors; Temperature Sensors | ||||

C-Series

The Airex C-Series motors provide a low overall height and are ideal for compact or micro stages. Airex linear motors are thinner than most of our competitors’ motors, but still offer you top performance and superior settling.

| units | C10 | C12 | C16 | |

|---|---|---|---|---|

| Coil and Magnet Track Assembly Width | mm | 10.00 | 12.68 | 10.00 |

| Coil and Magnet Track Assembly Height | mm | 42.42 | 42.26 | 42.42 |

| Coil Lengths (Inside Magnet Track) | mm | 30.7 - 244.1 | 61.2 - 244.1 | |

| Magnet Track Length | Configurable in 30.5 mm increments | |||

| Continuous Force | N | 4.2 - 42.0 | 10.2 - 50.3 | 17.8 - 99.2 |

| Peak Force | N | 8.0 - 116 | 20.0 - 142 | 36.0 - 247 |

| Connection Options | Delta or Wye; Series | |||

| Sensor Options | Temperature Sensor | |||

Benefits of Airex™ Ironless Linear Motors

Customizations range from simple metric holes to special models specific to your requirements. Categories of customization include:

- Added holes that ease assembly, assist motor mounting and integrate special functions

- Special mounting brackets or custom integration of coil assemblies into customer stages

- Special cables

- Special thermal sensors

- Vacuum compatibility via special fasteners, bleed channels, special platings or materials

- Cleanroom features including special cleaning and packaging

- Custom and private labeling

- Multi-unit coil modules

- Special magnet tracks

- Bracketless coil assemblies (ideal for integration into your stage)

Common Uses for Ironless Linear Motors

With Airex’s patented coil winding technology our linear motors are the ideal solution for actuators, precision stages, photonics platforms, semiconductor equipment, pick-and-place systems and inspection systems that require exceptionally responsive control at high bandwidths while simultaneously maintaining a low heat rise. Your solution may require an IRON core linear motor, utilizing high-temperature rare-earth magnets, from our P-Series or C-Series linear motors (all customizable).

Our motor is ideal in ultra-precision direct drive systems. The high intrinsic coil stiffness we employ eliminates backlash and windup inherent in other linear driven systems. Airex’s linear motors also eliminate the wear problems typically associated with ball-screws, belt drives and rack-and-pinion linear motion systems.

This expertise grants precise control at low velocity and superior point-to-point settling times. Our manufacturing method ensures precision placement of the conductors with minimal end turns, providing the highest slot fill in the industry as well as the best thermal path available on the market. High-energy, rare earth magnets complete the magnetic circuit.