Custom Motors

At Allient, we design and manufacture a wide variety of motors, and we can customize these motors to meet your exact application needs. Whether you have a unique form factor, demanding performance requirements, or special environmental considerations, we specialize in providing the right motor for your application.

Examples of our custom motion solutions are frameless torque motors, linear motors, axial flux motors, servo motors, slotless motors, and more. All of which can be integrated into custom linear or rotary actuators equipped with combinations of mechanical transmission, feedback devices, motor drive electronics, and integrated brakes, designed to meet your requirements.

Quick Design Turnaround

Design time includes refining the specification, designing, and getting documents ready for production. Typical design time is < 2 weeks and can be as short at 2 days.

Special Materials and Cleaning

It is common for motors to be used in Space, or in harsh environments. Sometimes it takes alternate materials to handle environmental conditions, such as stainless steel parts.

Special Environments

Vacuum, space, oil-submerged, partial hydrogen, and biological are all environments Allient has designed motors to operate in. Material selection all the way down to epoxies and material coatings, need to be evaluated to ensure reliability and performance.

Extreme Temperature

Temperatures up to 200°C and as low as -70°C are possible with proper selection of materials, including insulation, grease, electronic component selection, and magnet type. Sometimes high reliability means designing for high temperature even when you don’t expect high temperature. Low temperature down to -70 C.

Low Weight

Minimizing weight is done by optimizing the magnetic structure and coil volume. Higher pole counts can increase efficiency at lower operating speeds and also minimize motor weight.

Medical Rated Including the Human Body

Hermetically sealing of motor components. Depending on the application this may include enclosing motor magnets and coils. The appropriate material types and processes for enclosing with Titanium and Stainless include laser welded (and leak tested). Motors for Autoclave sterilization.

Need a custom motor?

Contact us today to schedule a call with our Solutions Center.

Custom Motor Specifications

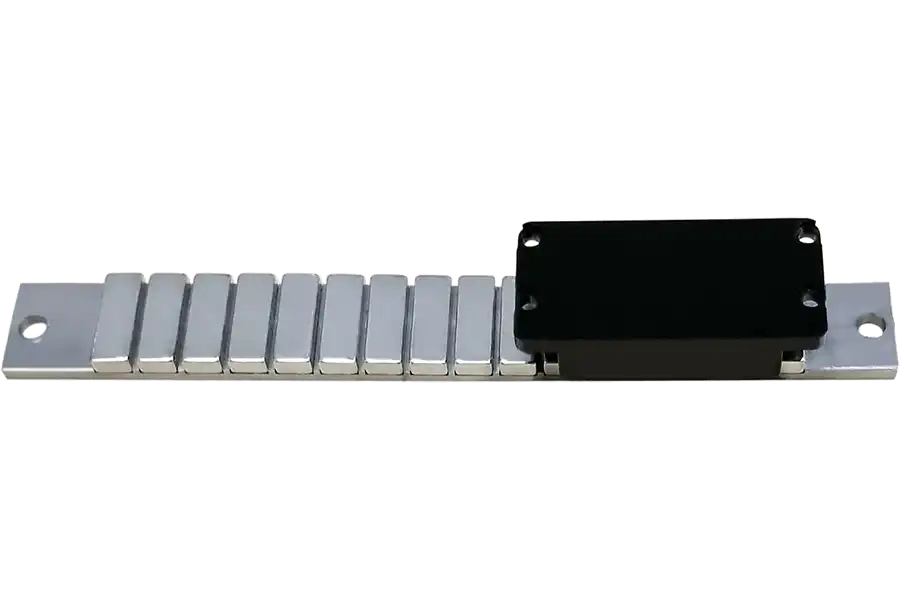

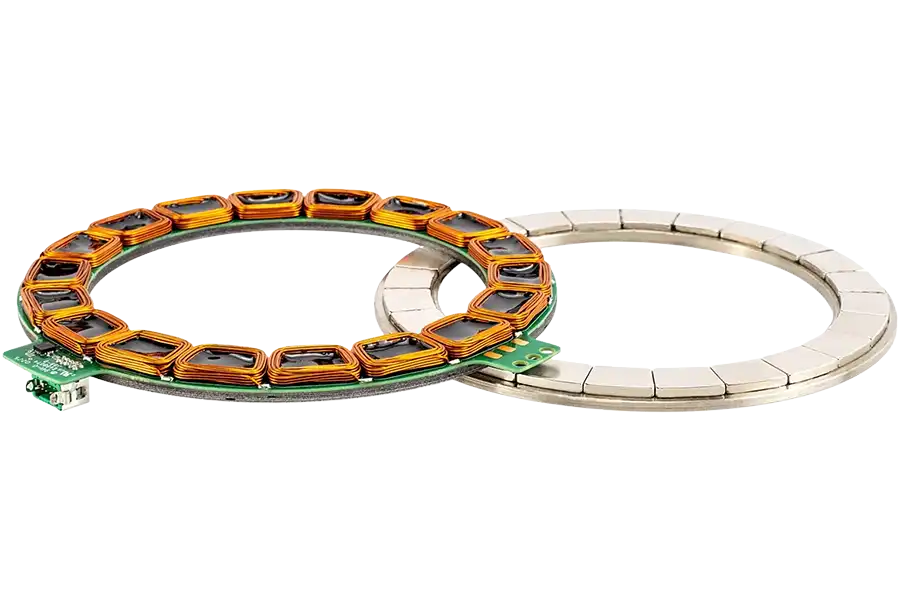

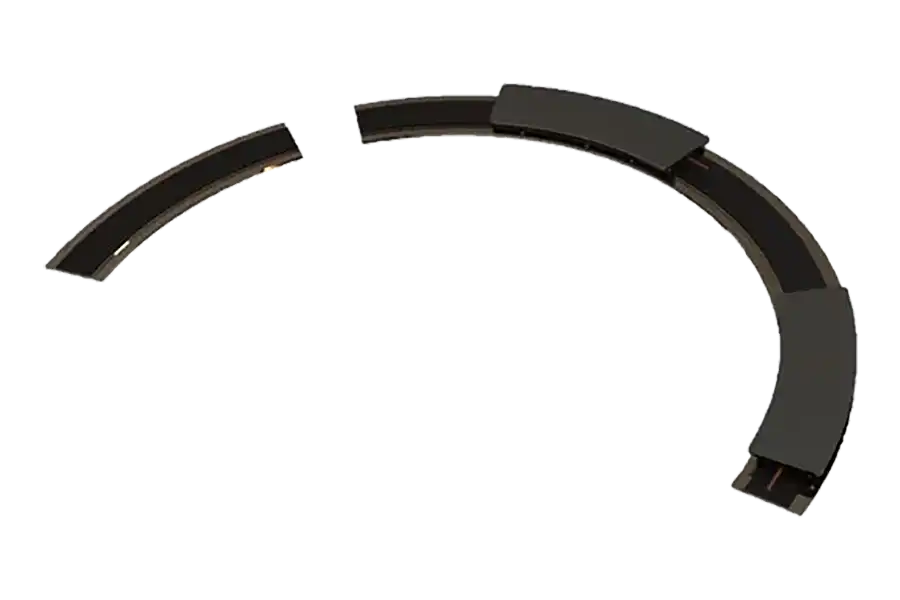

Motor configurations range from 8 mm diameters to 2 meters in diameter, and low profile linear down to 5 mm high. Large motors are typically modular in construction using arc-shaped segments. Axial flux motors up to and beyond 2 meters in diameter or rotating gantry stages. Allient will discuss the requirements with you and arrive at both mechanical and electrical parameters while predicting torque, speed, efficiency and other performance attributes.

Specifications Overview

-

Diameter (mm)8 - 2000

-

Length (mm)3 - 100

-

Modular ConstructionArc segments or linear segments

-

Vacuum (Torr)10 - 9

-

SpaceSpace radiation rated

-

High Temperature (°C)200

-

Low Temperatures (°C)-70

-

High Torque ConstantOptimized for low speed operation

-

Low Voltage ConstantFor low voltage and high speed operation

Types of Custom Motors

Custom Direct Drive Motors

Custom Voice Coil Motors

Custom Linear Motors

Custom Axial Flux Motors

Custom Vacuum Motors

Custom Torque Motors

Custom Frameless Motors